CleaX-V®

Anti-Fog & Anti-Fouling Film

Comprehensive Solution of Fog & Foul Issue

Product structure principle and application

Basic struction: 5 layers structions, main substrate is optical PET film, coating Hydrophilic layer, covered PE protection film, the other PET side coating PSA glue layer, covered release film.

We also provided customized structure.

1.PET + Hydrophilic layer + PE layer.

2.TPU( extensible film) + Hydrophilic layer + PE layer

3.Direct Coating Hydrophilic layer to target layer.

4.High water absorption layer + Hydrophilic layer + PE.

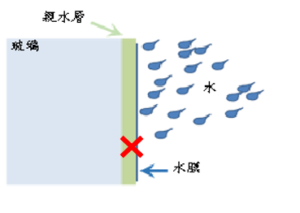

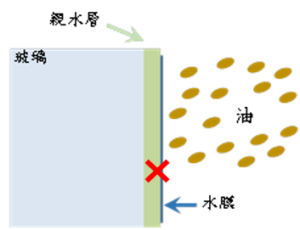

With Hydrophilic layer’s characteristic, the water will form a water layer on film, and move water, and not easy dirt attach.

Characteristic

Anti-Fog

Glass does not fog

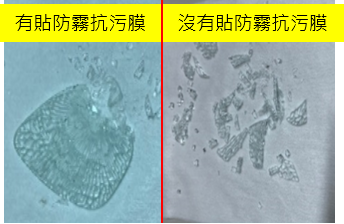

Not Easy Dirty

Not easily stained with dirty and dust

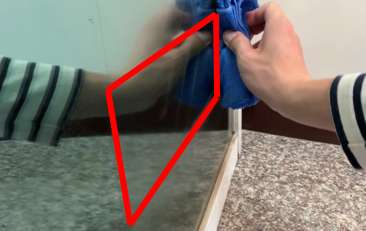

Easy Clean

Easy to clean if stained dirty

Explosion Proof

Glass explosion-proof is not easily broken

Protection Film

Not easy to get dust

Anti-UV

UV blocking rate 90%

Anti-Fog

Anti-Fouling

Anti-Fog

Easy-Clean

Non-Toxic&

Anti-Bacteria

食品工業發展研究所

Fogging

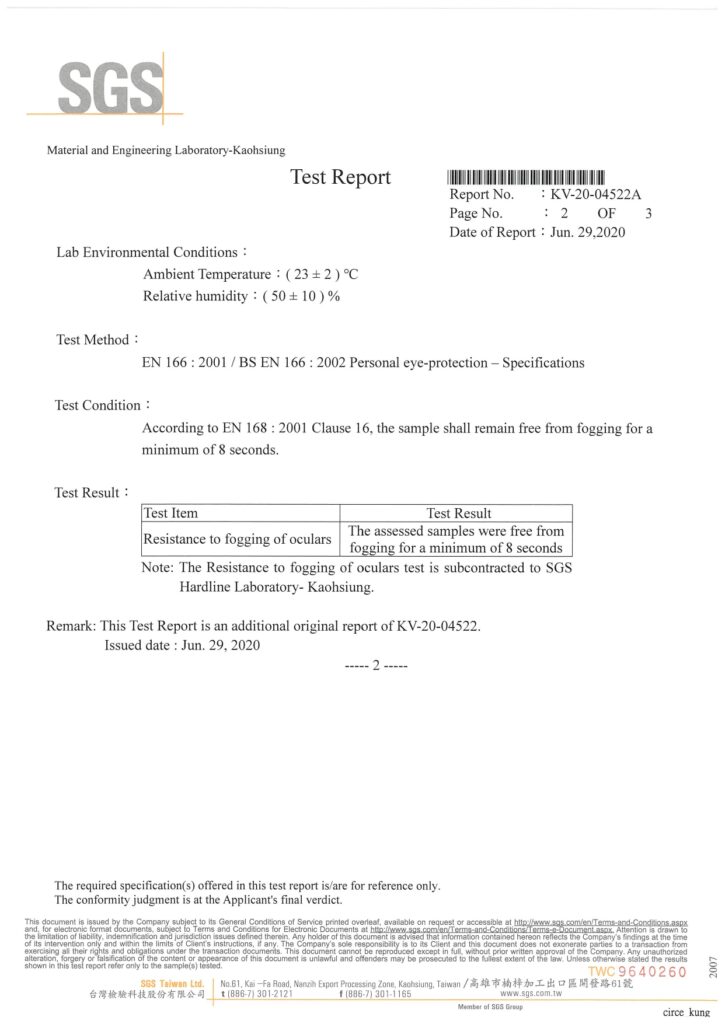

EN166 2001

K Mark

EN168 2001

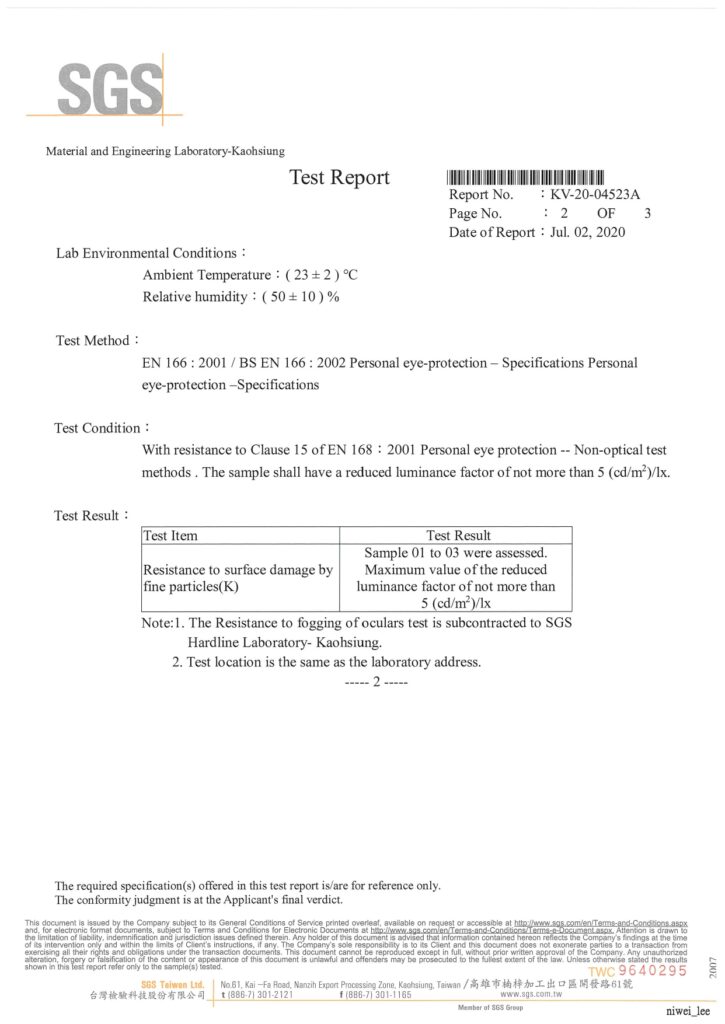

Non-Toxic

RoHS2011/65/EU Annex

Cd鎘/Pb鉛/Hg汞/Cr6+六價鉻/

多溴聯苯PBB/多溴聯笨醚PBDE

Water Angle

JIS R3257(1999)Testing method of wettability of glass substrate

TVOC

Rub Resistance

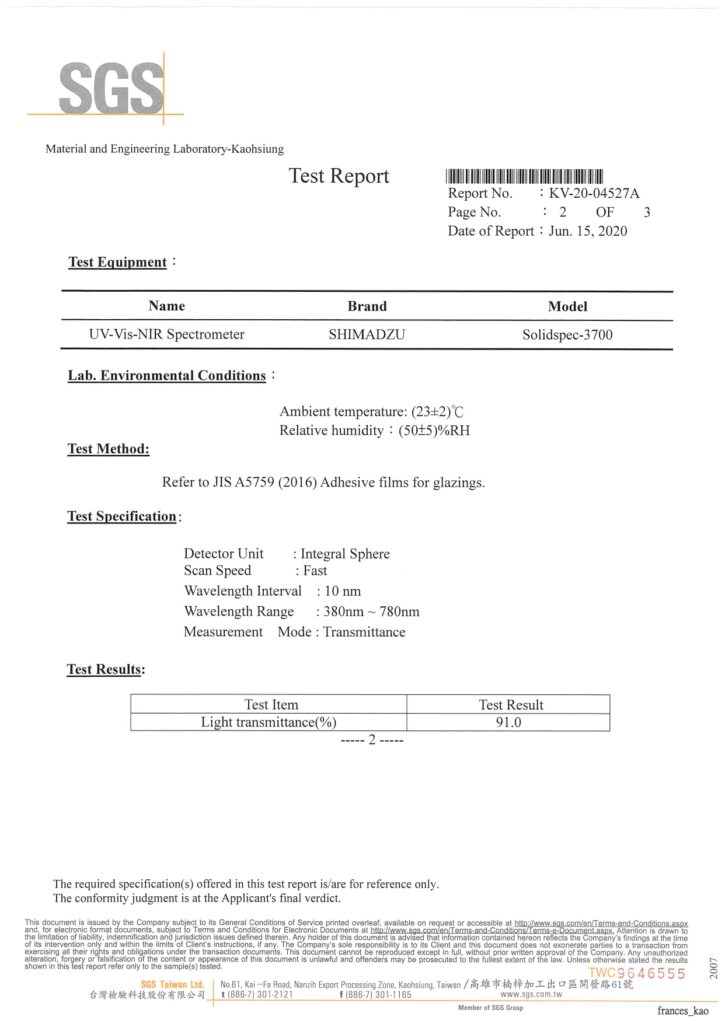

Light Transmittance

JIS A5759(2016) Adhesive films for glazings 91%

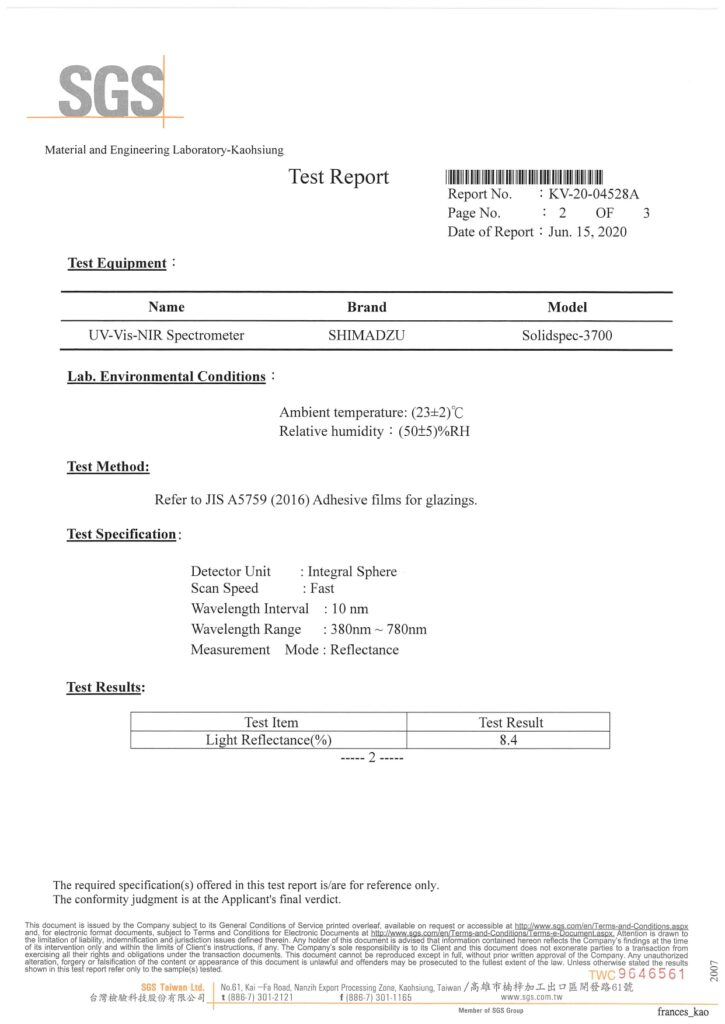

Light Reflectance

JIS A5759(2016) Adhesive films for glazings 8.4

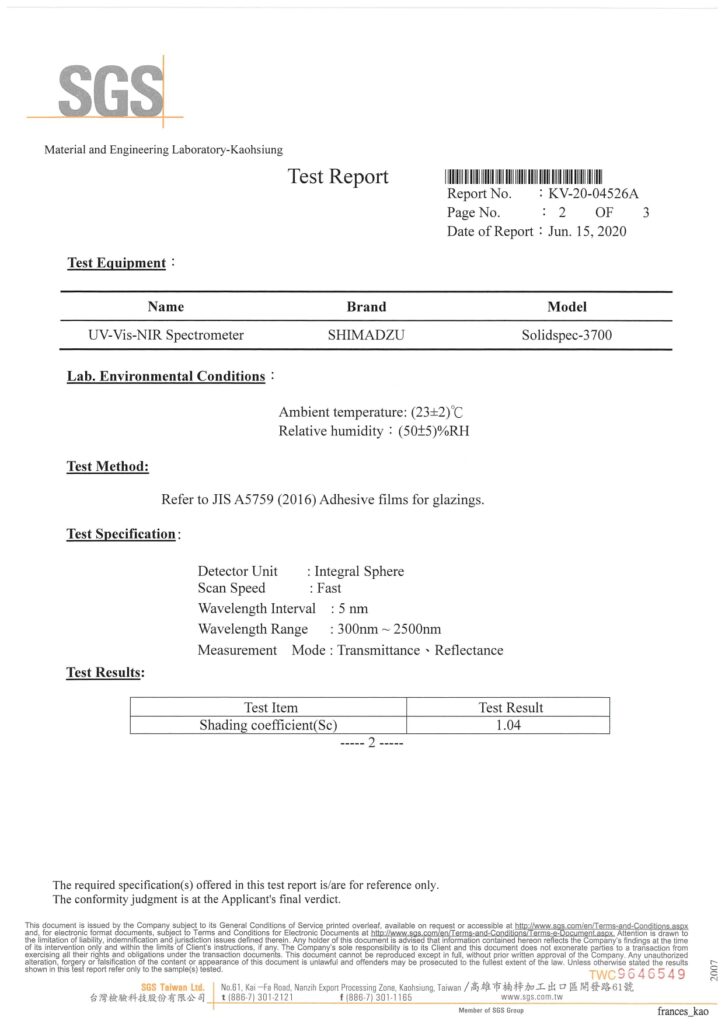

Shading Coefficient

JIS A5759(2016) Adhesive films for glazings 1.04

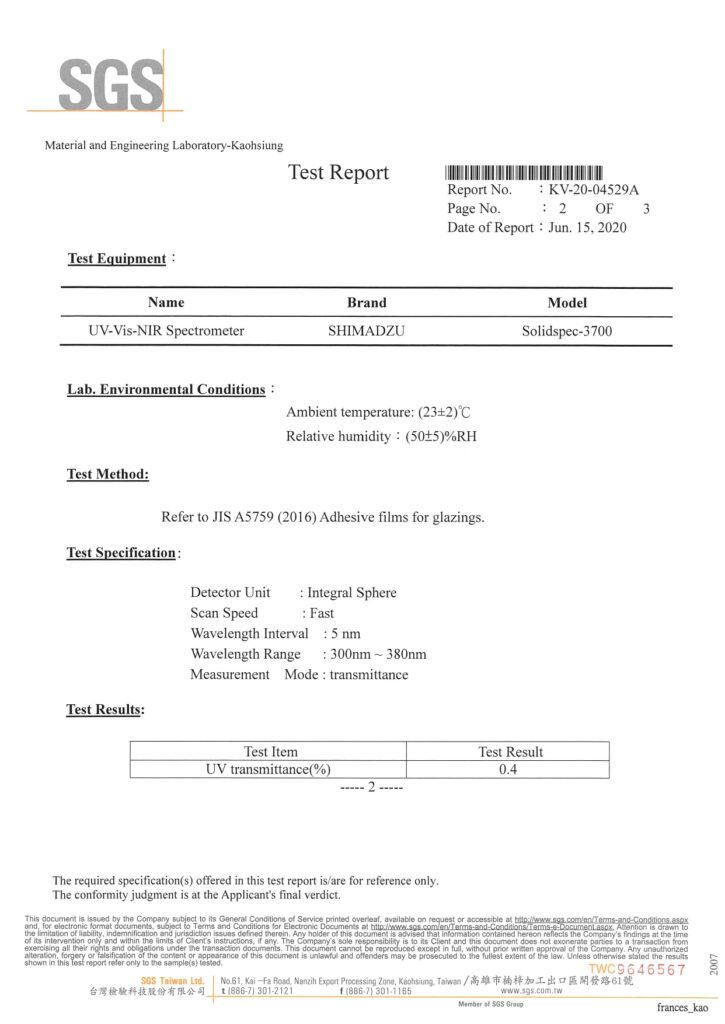

UV Transmittance

JIS A5759(2016) Adhesive films for glazings 0.4

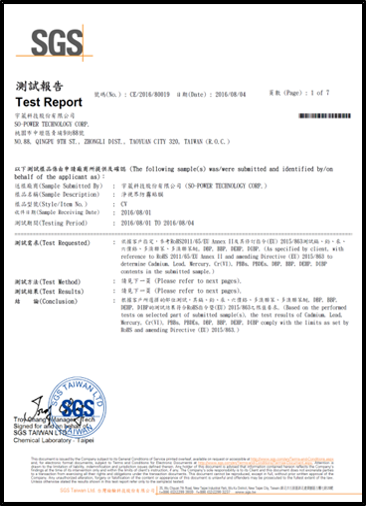

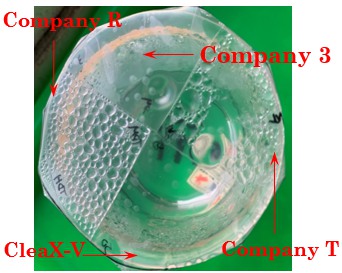

Competitor Comparison Table

| CleaX-V | Co. 3 | Co. R | Co. T | |

| Cold Fog Test(4℃) | ◎ | ○ | ||

| Steam Test(60℃) | ◎ | ○ | ||

| Vaper Test(25~35℃) | ◎ | ○ | ||

| Pencil Hardness Test | ○ | ◎ | ○ | ◎ |

| Adhesion Test | ◎ | ◎ | ◎ | ◎ |

| Transmittance | ◎ | ◎ |

◎:Performance Excellent

○:Performance Good

Conclusion: CleaX-V is better than competitors.

CleaX-V®

Anti-Fog & Anti-Fouling Film

Application 1

Diving Goggle

Protection Goggle

Snow Goggle

Sport Goggle

Swim Goggle

Helmet Mask

CleaX-V®

Anti-Fog & Anti-Fouling Film

Application 2

Hotel Mirror

Shower Door

KitchenBacksheet

Glass Door

Marble Protection

Yacht

Freezer Show Case

Cake Show Case

CleaX-V®

Anti-Fog & Anti-Fouling Film

Application 3

Auto

Electronic